Industrial Robot | BRTIRUS1820A Six-Axis Robot | Support OEM

- Model

- BRTIRUS1820A

Item specifics

- Control System

- HC Control System

- Color(General)

- red

- Loading Ability

- 20kg

- Arm Length

- 1850mm

- Repeated Positioning accuracy

- ±0.05mm

- Weight

- about 230kg

- Protection grade

- IP54 at the wrist and IP40 at the body

- Accessories

- teach pendant and electrical box

- Power Supply

- 220V

- Mpa

- 0.5~0.7MPa

Review

Description

Six-Axis Industrial Robot Product Features

BRTIRUS1820A SIX-AXIS ROBOT

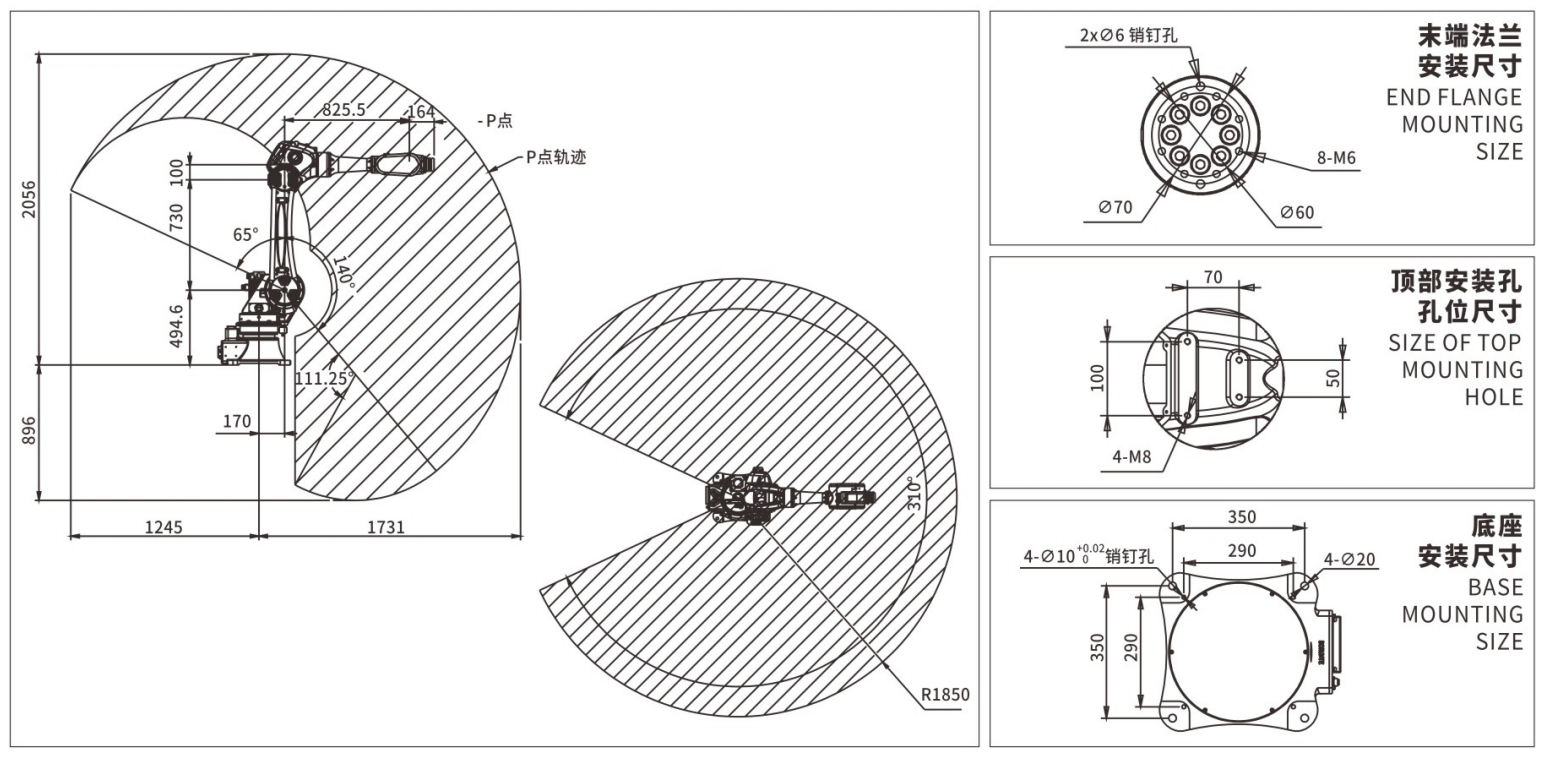

BRTIRUS1820A is a six-axis robot developed by ROBOTIC for complex applications with multipledegrees of freedom. The maximum load is 20kg,the maximum arm length is 1850mm. Lightweight arm design,compact and simple mechanical structure,in the state of high speedmovement,can be carried out in a small workspace flexible work,meet the needs of flexibleproduction. It has six degrees of flexibility. Suitable for loading and unloading,injection machine,die casting,assembling,coating industry,polishing,detection etc.It is suitable for injectionmolding machine range from 500T-1300T.

The protection grade reaches IP54 at the wrist and IP40 at the body.

The repeat positioning accuracy is±0.05mm.

Six-Axis Industrial Robot Main Specification

| Model: | BRTIRUS1820A | |||

| Range(Arm): | J1:±155° J2:-140°/+65° J3:-75°/+110° | |||

| Range(Wrist): | J4:±180° J5:±115° J6:±360° | |||

| Max.speed(Arm): | J1:110.2°/s J2:140.5°/s J3:133.9°/s | |||

Max.speed(Wrist): | J4:272.7°/s J5:240°/s J6:375°/s | |||

Arm Length: | 1850mm | |||

Loading ability: | 20kg | |||

Repeated positioning accuracy: | ±0.05mm | |||

Power source: | 5.87kVA | |||

Weight: | About 230kg | |||

Application scenarios: | Handling, stamping, injection molding, grinding, cutting, deburring, gluing, palletizing, spraying, etc | |||

No further notice if the specification and appearance are changed due to improvement and other reasons.

Thank you for your understanding.

Six-Axis Industrial Robot Usage Precautions

Operating temperature: 0℃~40℃

Best temperature:15℃~25℃

Relative humidity:20~80% RH(No condensation)

The operational stability and service life of six-axis robots are closely related to the environmental temperature and humidity. When installed and used under suitable temperature and humidity conditions, it can not only ensure the efficient and stable operation of the robot, but also significantly extend its service life.

Six-Axis Industrial Robot FAQ

How to choose the right Six-Axis Industrial Robot?

The following factors should be considered when choosing the six-axis robot:

Working scenarios: Robots of different specifications and models are suitable for different working scenarios, such as welding, palletizing, spraying, injection molding, die-casting, stamping, CNC lathes, grinding and quality testing, etc.

Load capacity: The load range of the robot covers 1 to 500 kilograms. For non-standard automated equipment, structural strength design and mechanical calculation will be carried out based on the size and weight of the workpiece.

Positioning accuracy: The repeat positioning accuracy of the robot can reach ±0.01-±0.5mm. The specific accuracy parameters depend on the specific production process requirements you provide.

Arm span range: The arm span range of the robot covers 600-3000mm, suitable for various scenarios.

If you are not sure how to choose the right robot, please feel free to contact our technical team at any time. We will provide professional advice based on your application scenarios and production needs.

What is the minimum order quantity (MOQ) for Six-Axis Industrial Robot?

The minimum order quantity (MOQ) is 1 piece. Whether it is standard products of robots and mechanical hands or customized non-standard automated equipment, the minimum order quantity is one piece. Every cooperation is an opportunity to establish a long-term partnership. Even for small orders, we will spare no effort. RBTC looks forward to expanding from small to large and becoming your reliable partner.

Do you offer customized Six-Axis Industrial Robot services?

We offer personalized customization options to meet specific requirements in application scenarios:

Customized robot solutions: Based on your production needs, we provide customized robot solutions.

Non-standard customization: Design and customize non-standard automated equipment according to your needs to meet application requirements.

Color: The color options can be changed to meet specific industry standards and aesthetic standards.

Do you provide six-axis robot technical training? What does the training content include?

We offer flexible and diverse technical training services to our clients, supporting both online and offline modes:

Online training: Relying on remote communication technology, teaching is conducted through instant messaging software, video conferencing and other tools, breaking geographical restrictions and making it convenient for customers to learn at any time.

Offline training: We can provide on-site training services abroad based on customer needs, or invite trainees to our company's professional training venues for learning. We support systematic training throughout the entire process, covering core knowledge such as equipment operation norms, programming and debugging skills, basic maintenance and care, fault diagnosis and elimination. The training method adopts a combination of theoretical explanations and practical exercises to ensure that trainees master the skills solidly. In addition, to ensure that trainees can focus on their studies, we will also properly arrange accommodation and meals for them during the company's training period, so they have no worries.

How long is the warranty period for a six-axis robot? What services are provided during the warranty period?

Our products come with a one-year warranty service. During the warranty period, for non-human-caused damaged parts, we will provide replacement accessories free of charge.

What is your delivery time?

For existing products, they will be shipped within 7-15 days after payment.

For customized products, the customization period is 30-90 days.