How do cobots work with humans?

- Share

- publisher

- RBTC team

- Issue Time

- Sep 30,2025

Summary

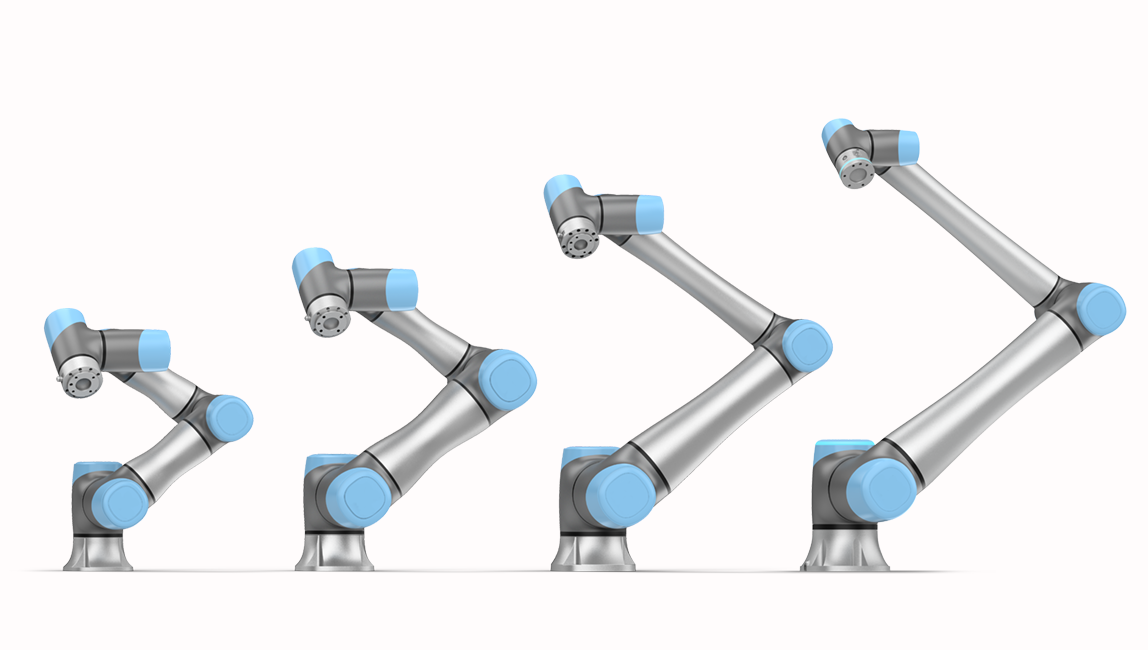

Goodbye to "humans avoiding machines"! Humans and cobots can "work hand-in-hand" seamlessly in the same space—completely replacing the isolated model of traditional industrial robots where "humans and machines stay on separate sides"!

Goodbye to "humans avoiding machines"! The core of cobots working side by side with humans lies in "being safe without injury" and "enabling more efficient collaboration". Humans and robots can "work hand-in-hand" seamlessly in the same space—completely replacing the isolated model of traditional industrial robots where "humans and machines stay on separate sides"!

I. Safety Mechanism Guarantee

For cobots to work side by side with humans? Safety must come first! They minimize risks through three key ways:

The outer shell uses lightweight materials like carbon fiber and aluminum alloy, with joints equipped with cushioning—even if it hits a human, there’s no impact force.

Built-in torque sensors are highly sensitive; upon contact with a human or obstacle, they immediately slow down or even stop.

They are also equipped with "eyes" like 3D cameras and LiDAR, which monitor human positions in real time: if a human enters the core work area, the robot slows down; if someone enters a hazardous area, it shuts down immediately.

II. Core Interaction: Human-Robot Communication Methods

For cobots to work with humans smoothly, how to communicate? These 3 intuitive methods let them understand you without complex operations!

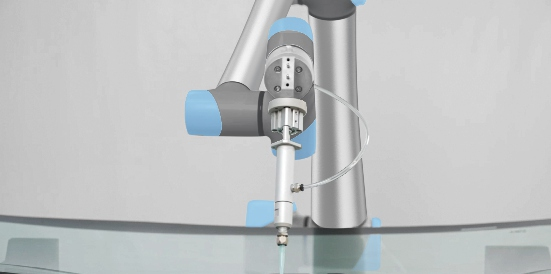

Want to teach it a path? Just pull the robotic arm! It has a force sensor and can accurately memorize the path.

Adjusting parameters is easy too—use a tablet to set gripping force, movement path, etc. No programming skills required, even beginners can handle it.

It can also be controlled by voice! Shout "grab the part" and it moves. After finishing, it will even respond, "Part grabbed, waiting for next step." For example, during electronic device assembly, you focus on wiring—just call out, and the robot hands you tools. Super hassle-free!

III. Collaborative Logic: Human-Robot Complementary Division of Labor

The key to human-robot collaboration is letting "humans do what they’re good at, and robots do what they’re efficient at" — the right division of labor doubles efficiency! These 3 cooperation modes are super practical:

Human-led, Robot-assisted: Humans hold the "decision power" (handling tasks requiring judgment and flexibility), while robots act as "helpers" (doing repetitive, tiring work). For example, in automotive interior assembly: humans accurately align components like instrument panels, and robots simultaneously tighten bolts — no need for humans to lift wrenches, which is less tiring and more precise.

Robot-led, Human-supplemented: Robots take the "lead" (managing core sorting and assembly processes), and humans "fill gaps" (handling tricky situations). Like in e-commerce sorting: robots automatically sort standard cartons, but stop and alert when encountering soft bags or irregular packages; after humans sort them manually, robots continue working without mistakes.

Human-Robot Synchronous Collaboration: Humans and robots "work together" on the same task at the same time. Take metal part polishing: robots hold parts and move along fixed paths, while humans use tools for simultaneous fine-grinding — robots ensure uniform polishing, and humans touch up dead spots, maximizing quality!

IV. Technical Support: Underlying Capabilities for Collaborative Operations

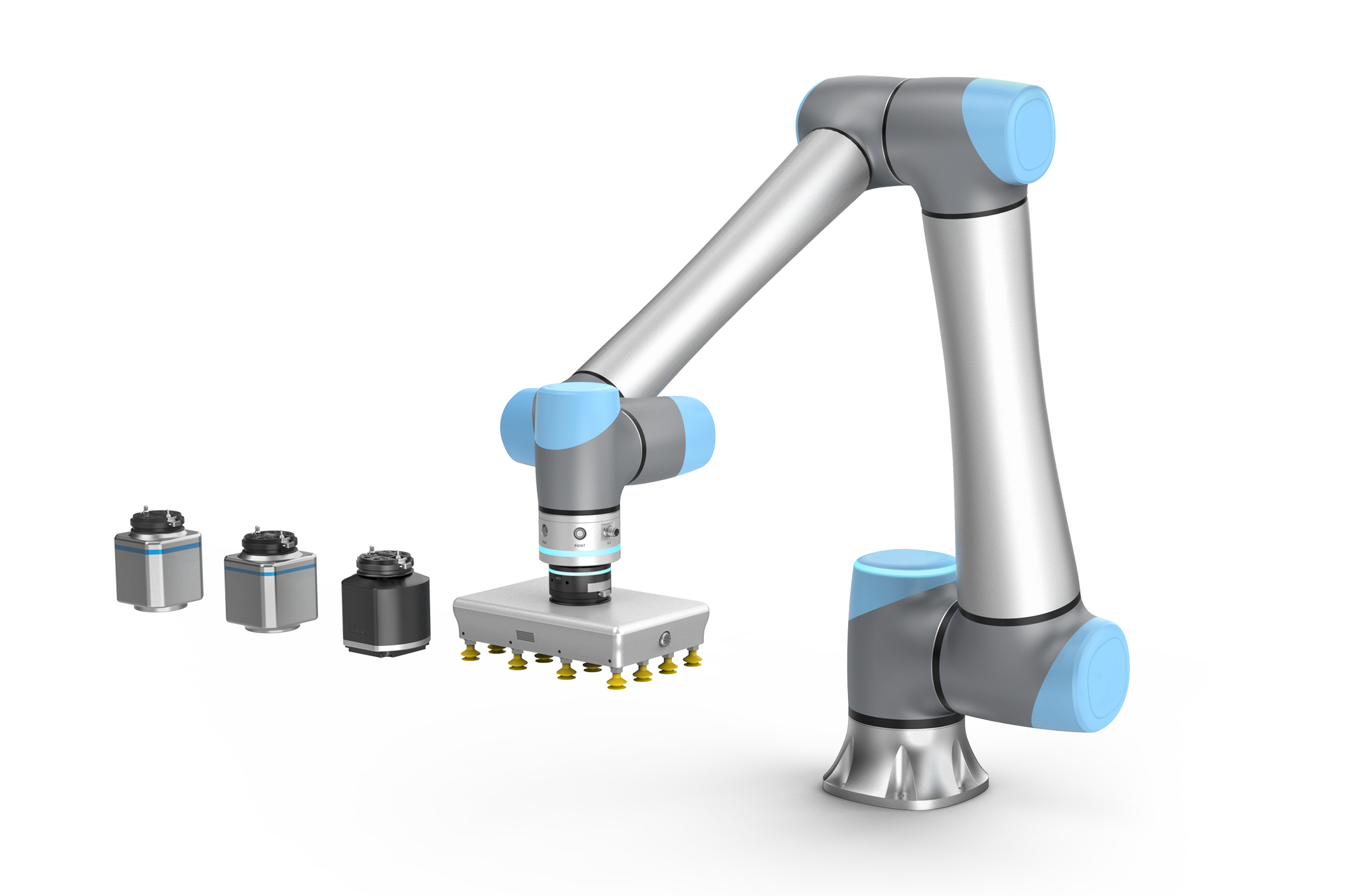

The seamless collaboration between collaborative robots and humans relies entirely on these three "super capabilities"—simply put: no random movements, adaptability, and accurate alignment!

"Super Sensing" for no random movements: Equipped with force, vision, tactile, and distance sensors, it maintains real-time awareness of: where humans are, their movements, whether parts are properly aligned, and if tools are in place — no random operations at all.

"Smart Brain" for adaptability: AI algorithms act as its "decision-making assistant." For example, if a human temporarily changes their working position, the robot immediately and automatically re-plans its movement path, without delaying the human’s work.

"Precision" for accurate alignment: Equipped with high-precision "motion components" like servo motors and reducers, its repetitive positioning accuracy is within ±0.02mm. Just as a human holds a part, the robot can accurately align with the part’s interface—no misalignment whatsoever, ensuring seamless collaboration!

Contact RBTC

If you are interested in our RBTC cobots,feel free to reach out to me for more details and a quote. And visit our website(www.iroboticplus.com/products-index.htm), or contact us at +86-13826981851 or Tommy@iroboticplus.com