Industrial Robots vs. Cobots: Which Is Right for Your Business?

- Share

- publisher

- RBTC team

- Issue Time

- Dec 15,2025

Summary

Compare collaborative robots and traditional industrial robots to find your best fit.

Industrial Robots vs. Cobots: Which Is Right for Your Business?

Industrial robots and cobots are transforming the manufacturing landscape. They offer unique benefits and challenges for businesses.

As an expert in robot automation solutions, RBTC hopes to help users understand the core differences between the two types of robots and match suitable solutions, making informed decisions on automation transformation.

Industrial robots are known for their speed and precision. They excel in large-scale manufacturing environments.

Cobots, or collaborative robots, are designed to work alongside humans.

Cobots are gaining popularity in smaller operations. They are equipped with advanced sensors and safety features.

This makes them safe to work with human workers.

Tailored to their characteristics and application scenarios, RBTC offers end-to-end services spanning selection analysis, solution design, equipment integration, and on-site commissioning.

Only the right robots and solutions drive optimal ROI for your business. We customize automation plans based on your real data and roadmap to eliminate blind investment risks.

Choosing between industrial robots and cobots depends on several factors. These include production volume, task complexity, and budget. Each type of robot solution offers distinct advantages.

Industrial robots are ideal for repetitive, high-volume tasks.Cobots, on the other hand, offer flexibility and ease of programming. They are suitable for businesses with limited robotics expertise.

The global market for both types of robots is growing. This growth is driven by advancements in automation technology. Businesses must assess their needs to choose the right solution.

This guide will help you navigate the world of manufacturing automation with RBTC’s professional insights. It will provide insights into the benefits and challenges of industrial robots and cobots.

Summary

This guide compares industrial robots and cobots, explaining where each excels and how to choose between them.

Industrial robots deliver speed, precision, and throughput for high-volume, repetitive tasks but require safety barriers and specialist programming.

Cobots prioritize collaboration, safety, and ease of deployment, suiting dynamic, smaller-scale operations with changing tasks.

The right choice depends on production volume, task complexity, budget, integration needs, and growth plans amid rapid advances in AI and IIoT.

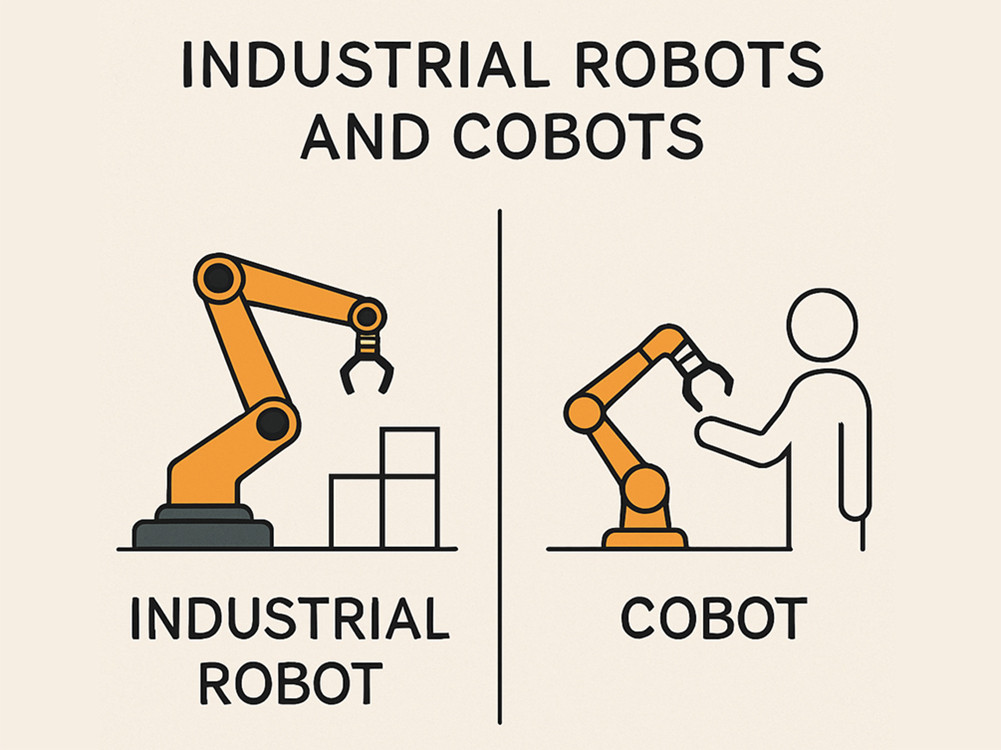

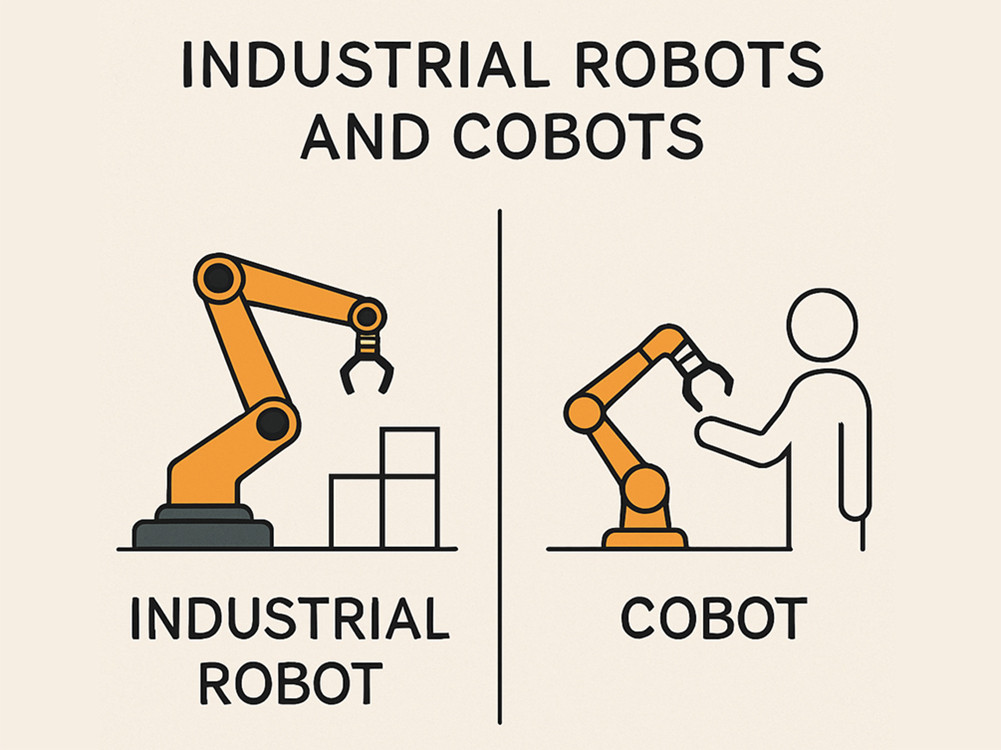

Understanding Industrial Robots and Cobots

Industrial robots have been a staple in manufacturing for decades. They perform tasks with high accuracy and speed. These robots are often found in environments requiring heavy-duty automation.

Cobots, or collaborative robots, represent a newer wave in robotics. Their design allows them to work closely with people. Cobots are frequently utilized in settings where human-robot interaction is crucial.

The key distinction between industrial robots and cobots lies in their intended use and design. Industrial robots are built for tasks like welding and painting.

Meanwhile, cobots focus on tasks requiring human cooperation.

Features of each robot type:

Industrial Robots: High precision, requires safety barriers, suited for large-scale production.

Cobots: Advanced sensors, collaborates with humans, easy to program and deploy.

In summary, both robot types serve unique roles. Industrial robots excel in speed and efficiency. Cobots shine in adaptability and human-robot collaboration.

Understanding these differences helps businesses in their automation journey.

RBTC’s customized automation solutions are tailor-made for small and medium-sized enterprises (SMEs), enabling cost-effective production line upgrades.

Contact us for a free solution proposal today.

Key Differences Between Industrial Robots and Cobots

Industrial robots and cobots vary significantly in design and application. These differences impact their suitability for various business needs.

Firstly, industrial robots are typically more robust and powerful. They are designed to handle heavy and high-speed tasks. This makes them ideal for large-scale operations like automotive assembly.

Conversely, cobots are built for versatility and collaboration. They are often smaller and equipped with sophisticated sensors. This allows them to work safely alongside humans without barriers.

Another important difference is in their programming complexity. Industrial robots often require specialized knowledge to operate. Cobots, however, are user-friendly and easier to program, even for non-experts.

In terms of cost, industrial robots generally demand a higher initial investment. However, they offer unmatched efficiency for high-volume production. Cobots, while less expensive upfront, provide flexibility and quicker redeployment.

Here are the key differences at a glance:

Tasks: Industrial robots for repetitive, cobots for varied.

Safety: Barriers needed for industrial robots, cobots integrate safety features.

Programming: Complex for industrial robots, simple for cobots.

Ultimately, the choice depends on your business's specific automation needs.Understanding these differences helps in making an informed decision.

Both robot types contribute valuable capabilities to industrial automation.

Advantages of Industrial Robots in Manufacturing Automation

Industrial robots offer several benefits for manufacturing automation.

They help increase productivity by performing tasks quickly and with precision. Speed and accuracy are their defining strengths in large-scale environments.

One major advantage is their ability to handle repetitive tasks tirelessly.

Industrial robots excel in tasks like welding, painting, and assembly. This leads to greater output and consistent product quality.

Another benefit is their durability and efficiency. They are engineered to perform in harsh conditions without frequent breakdowns. This reliability reduces downtime and maintenance costs.

Furthermore, industrial robots contribute to worker safety. By taking on dangerous tasks, they protect human workers from potential hazards.

This minimizes workplace injuries and enhances job satisfaction.

Here's a brief list of their advantages:

High Speed: Execute tasks faster than humans.

Precision: Maintain consistent quality.

Durability: Operate efficiently under challenging conditions.

In summary, industrial robots are invaluable in environments requiring rapid, repetitive work. Their role in optimizing production processes is undeniable.

For businesses aiming for mass production, they are an essential asset.

For large-scale, high-repeatability production needs, RBTC provides robots and scenario-specific solutions to help businesses quickly build stable, high-efficiency automated production lines.

Advantages of Cobots for Industrial Automation

Cobots, or collaborative robots, are designed to work alongside humans.

Their primary advantage lies in their collaborative nature. They seamlessly integrate into human-driven workflows, enhancing efficiency without displacing workers.

Cobots are incredibly versatile.

They can be quickly reprogrammed for various tasks like packaging, quality inspection, and machine tending. Their adaptability makes them perfect for dynamic manufacturing setups where tasks change frequently.

One of the standout features is their built-in safety.

Cobots are equipped with advanced sensors and safety features, allowing them to work safely around people. This reduces the need for extensive safety barriers, saving space and cost.

Moreover, the ease of programming cobots means less downtime. Businesses with limited robotics expertise can still benefit from automation.

This accessibility opens opportunities for smaller enterprises seeking to enhance their production capabilities.

Here's a summarized list of cobots advantages:

Versatility: Adapt to different tasks easily.

Safety: Operate safely alongside humans.

Ease of Use: Simple programming facilitates quick deployment.

Overall, cobots provide a flexible and cost-effective automation solution. They enhance productivity while maintaining a safe work environment, making them ideal for small to medium-sized enterprises.

For any requirements, contact RBTC promptly for scenario-specific cobot selection guidance and solution proposals.

Safety Considerations: Industrial Robots vs. Cobots

Safety is a crucial concern in manufacturing automation.

Industrial robots typically operate behind safety barriers, isolated from human workers. These barriers prevent accidents, but they also require significant space and additional costs.

Cobots, on the other hand, are designed to operate safely alongside human workers. They feature advanced sensors and software that allow them to detect and respond to human presence.

This capability significantly reduces the risk of injury and eliminates the need for bulky safety barriers.

However, the regulatory standards governing industrial robots and cobots vary. It's imperative for businesses to adhere to these regulations. Compliance ensures not only safety but also shields companies from potential liabilities.

Here's a quick safety comparison:

Industrial Robots: Require barriers; restricted human interaction.

Cobots: Built-in safety features; designed for close proximity to humans.

In conclusion, while both robot types have safety protocols, cobots offer more flexible and human-friendly safety solutions. This characteristic is especially valuable for environments where space is at a premium and human interaction with robots is frequent.

Flexibility and Ease of Integration

One of the key factors in choosing between industrial robots and cobots is their ability to integrate into existing systems. Cobots excel in flexibility and ease of deployment. They are designed to work alongside human workers and fit seamlessly into various workflows. This characteristic makes them suitable for businesses of all sizes.

In contrast, industrial robots are typically more complex to integrate. They require customized programming and safety measures. This makes them well-suited for environments where they can work independently from human workers. While this setup might demand more time upfront, it can pay off in consistent, high-volume outputs.

Cobots can adapt to multiple tasks, such as packaging and quality inspection. This adaptability means they can be reprogrammed quickly. They are ideal for companies with changing production needs. In comparison, industrial robots are usually tasked with repetitive, high-speed processes like welding and painting, where consistency is key.

To summarize:

Cobots: Flexible, easy to integrate, reprogrammable for varied tasks.

Industrial Robots: Require more setup, ideal for specific, repetitive tasks.

When determining which robot solution to implement, consider how their integration will impact current operations and future scalability.

Therefore, choosing a reliable automation partner is equally crucial.

RBTC specializes in industrial automation and integrated solutions, providing industrial robots, scenario-specific solutions, and custom non-standard automation auxiliary equipment.

What’s more, we offer worldwide on-site installation, commissioning, and training after-sales services for global clients.

We sincerely aspire to be your trusted automation partner.

Case Studies: Applications by RBTC

RBTC robot solutions provides valuable insights into industrial robots and cobots .

A leading automotive manufacturer implemented industrial robots for welding and assembly.

These robots operated tirelessly, significantly increasing production throughput.

This resulted in faster production cycles and improved product quality.

In contrast, a small electronics company adopted cobots for their assembly line. Their cobots assisted human workers by handling delicate components.

This collaboration reduced errors and improved precision in tasks requiring finesse. As a result, the company experienced a boost in customer satisfaction and product reliability.

Another interesting example is a food processing plant.

The plant employed cobots for packaging and inspection. These cobots worked side-by-side with employees, ensuring strict quality control.

This integration led to enhanced operational efficiency and reduced product wastage.

Here's a summary of applications from these case studies:

Automotive Manufacturing: Industrial robots for welding and assembly

Electronics Production: Cobots for delicate component handling

Food Processing: Cobots in packaging and quality inspection

These case studies demonstrate the versatility of both industrial robots and cobots across various industries.

Each application proves the importance of choosing a robot solution that aligns with specific business goals and operational needs.

The Future of Manufacturing Automation: Trends and Innovations

Manufacturing automation is on the brink of transformative changes.Emerging trends are set to redefine how industries operate.

With technological advancements, robots are becoming smarter and more efficient.

The integration of artificial intelligence (AI) and machine learning (ML) into industrial robots and cobots is a major trend.

These technologies allow robots to learn from their environment, improving precision and functionality.

Consequently, businesses can achieve higher productivity and minimal errors.

Another exciting innovation is the rise of the Industrial Internet of Things (IIoT). IIoT connects devices, enabling seamless data exchange across manufacturing systems.

This connectivity fosters more integrated and adaptive robot operations.

Key trends and innovations to watch include:

AI and ML: Enhanced robot learning and adaptation

IIoT: Enhanced connectivity and data-driven decision-making

Advanced Sensors: Improved safety and operational accuracy

These trends suggest a future where robots and humans work more harmoniously. Companies need to stay informed and adapt to leverage these cutting-edge innovations.Staying ahead in the automation race requires embracing these emerging technologies.

Conclusion: Making the Best Choice for Your Automation Needs

Selecting the right robot solution depends on your unique business needs. Whether you opt for industrial robots or cobots, each offers distinct benefits. Analyze your production requirements, budget, and workforce capabilities.

Industrial robots are suitable for high-volume, repetitive tasks. They deliver speed and precision in large-scale operations. Cobots offer flexibility and are ideal for tasks that require human-machine collaboration.

They fit well in environments where safety and adaptability are priorities.

Ultimately, a thorough assessment of your operations and long-term goals is essential. Consider how each solution aligns with your strategies.

This thoughtful approach will ensure your investment enhances productivity and optimizes your manufacturing processes.

Contact RBTC to specify your requirements, and we will provide you with a free customized solution.