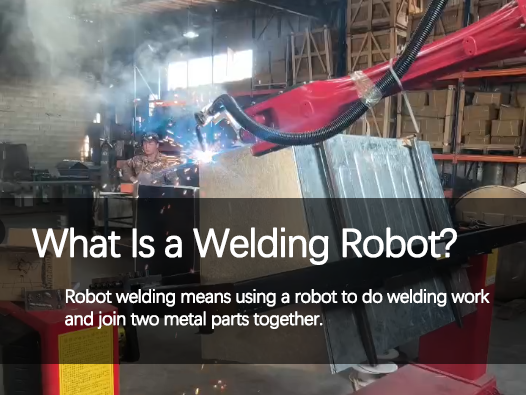

What Is a Welding Robot?

- Share

- publisher

- RBTC team

- Issue Time

- Nov 24,2025

Summary

Robot welding means using a robot to do welding work and join two metal parts together.More than half of all robots used in industry are for welding work.

Robot welding means using a robot to do welding work and join two metal parts together.

If you run a factory, you have probably heard how this kind of equipment changes how production works.

More than half of all robots used in industry are for welding work—and the reasons are easy to see:

If you run a factory, you have probably heard how this kind of equipment changes how production works.

More than half of all robots used in industry are for welding work—and the reasons are easy to see:

Welding robots can work all day and all night (24 hours a day, 7 days a week) without stopping. They weld things the same way every time, and they keep workers safe.

But the main thing to know: a good welding robot is not just a "robot arm with a welding gun". It is a full set of equipment made to fit what a factory really needs.

But the main thing to know: a good welding robot is not just a "robot arm with a welding gun". It is a full set of equipment made to fit what a factory really needs.

What Parts Are in a Welding Robot System?

A robot arm and a welding gun might seem like all there is to a welding robot. But to get the most out of automation, you need to think of the whole system as one thing:

Robot arm: It is strong and steady, and very easy to move. It can move in many directions, so it can reach any spot that needs welding—no matter the size or shape of the part. It works for small batches of custom parts and large batches of the same parts.

Robot arm: It is strong and steady, and very easy to move. It can move in many directions, so it can reach any spot that needs welding—no matter the size or shape of the part. It works for small batches of custom parts and large batches of the same parts.

Welding gun (with auto-clean system):This tool is at the end of the robot arm. It feeds welding wire smoothly. It has a built-in cleaner that removes welding waste quickly, so the gun does not get blocked. You don’t need to clean it by hand, which saves time.

Easy-to-use controller: With this controller, you can change settings or programs right there in the factory. This makes the whole system work faster.

Easy-to-use controller: With this controller, you can change settings or programs right there in the factory. This makes the whole system work faster.

At RBTC, we don’t just sell welding robots. We build a full set of equipment that fits what your factory really needs:

Safety first design: We include safety curtains, sensors and metal guards as standard. These keep workers safe from welding light, smoke and high heat.

Custom clamps:We make clamps just for your parts. They hold parts tight and can be changed quickly. If you need extra equipment like gantries or lathes, we can add them too.

Custom clamps:We make clamps just for your parts. They hold parts tight and can be changed quickly. If you need extra equipment like gantries or lathes, we can add them too.

We can add other things your factory needs—like conveyor belts, tables for loading/unloading parts, or inspection tools. This makes automation easy to use in your factory.

RBTC thinks that only reliable welding robots and solutions can help factories make more products and keep workers safe.

Since welding robot systems can be set up in many ways, we have a team of skilled engineers. They can make the best solutions for the problems your factory faces.

What Kinds of Welding Can Welding Robots Do?

A big plus of welding robots is that they can do almost all common types of welding:

MIG/MAG welding:Good for fast, simple welding (like making lots of metal frames or home appliance parts).

MIG/MAG welding:Good for fast, simple welding (like making lots of metal frames or home appliance parts).

TIG welding:Made for precise welding (like small, detailed parts for aerospace).

Spot welding:Needed in car factories—RBTC’s robots can do spot welding on metal sheets quickly and evenly.

Manual Welding or Robot Welding: Which to Choose?

Every factory owner asks this question—and there is no single answer. Manual welding is still useful for small batches, custom parts, or odd-shaped parts. But if you want to:

- Make every product with the same welding quality;

- Make more products without hiring more workers;

- Make your workshop safer;

- Waste less and spend less money.

Then RBTC’s welding robots and solutions are the best choice for you.

We won’t make you "change everything at once". You can start with one robot for one workstation, and add more as your business grows. Automation can fit your budget and needs.

Why Choose RBTC?

We are not just a company that sells robots—— We are your partner for automation. Our skilled team helps you all the way: we design solutions for your needs, install and set up the robots, train your workers, and help you after the sale.

We know welding, we know factories, and we know how to make automation simple to use.

If you are tired of bad welding quality, missing delivery dates, and safety risks in your workshop, it’s time to contact RBTC. Our welding robot solutions are made for real factories, real parts, and real results.