I.M.M Robot | BRTR Series Five-Axis Servo Manipulator | Support OEM

- Model

- BRTR Series

Item specifics

- Control System

- HC Control System

- Color(General)

- white

- Loading Ability

- 8-15kg

- Repeated Positioning accuracy

- ±0.05mm

- Power Supply

- 220V

Review

Description

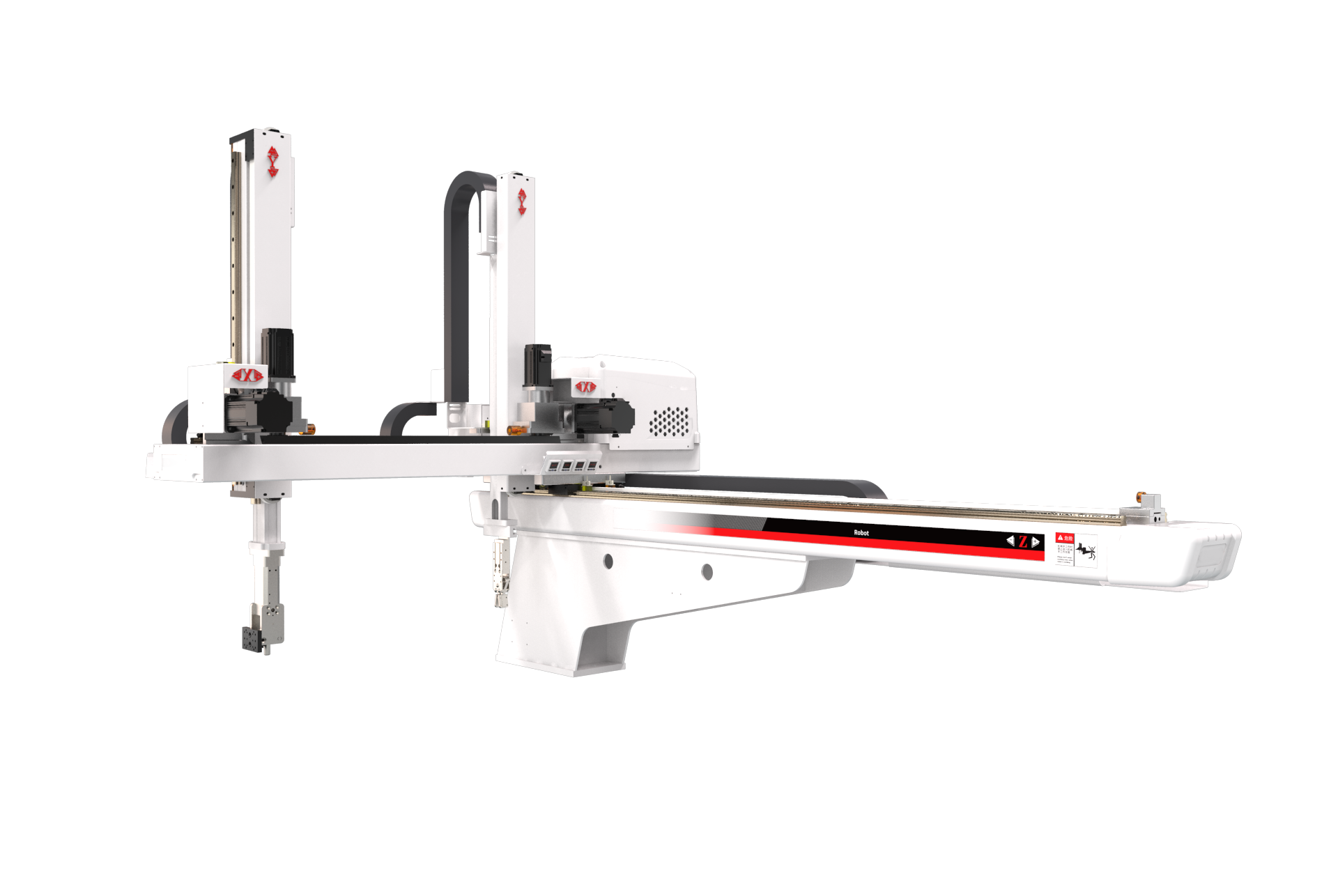

Five-Axis Servo Manipulator Product Features

BRTR09WDS5P0/F0 series applies to all types of horizontal injection machine ranges of 160T-320T for take-out products and sprue. The vertical arm is the telescopic stage with the product arm. Five-axis AC servodrive,also suitable for in-mold labeling and in-mold inserting application. After installing the manipulator,the productivity will be increased by 10-30% and will reduce the defective rate of products,ensure the safety of operators,reduce manpower and accurately control the output to reduce waste.

Five-axis driver and controller integrated system:fewer signal lines,long-distance communication,good expansion performance,strong anti-interference ability,high accuracy of repeated positioning,can simultaneously control multiple axes,simple equipment maintenance,and low failure rate.

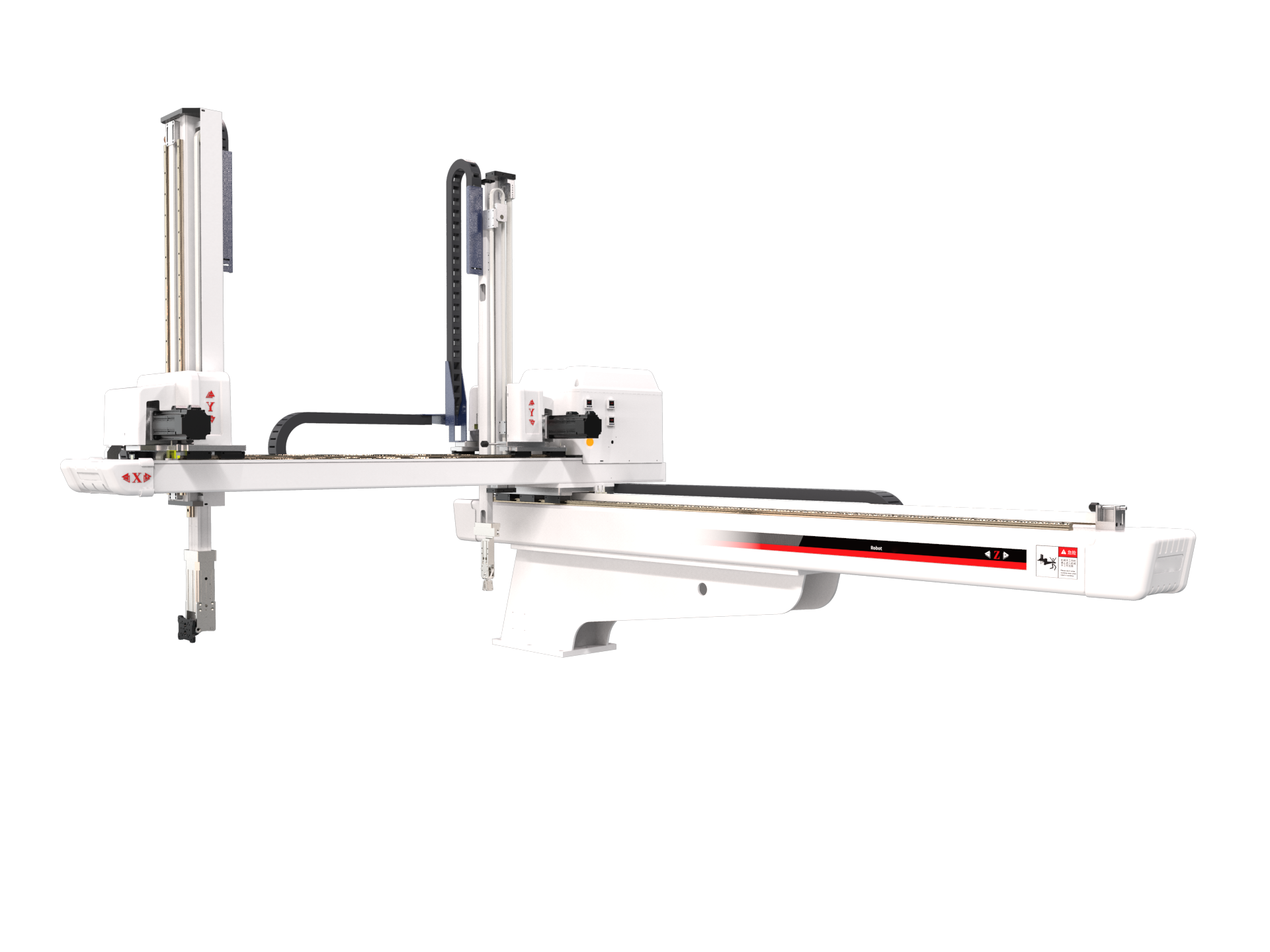

BRTR13WDS5PC/FC series applies to all types of horizontal injection machine ranges of 360T-700T for take-out products and sprue. The vertical arm is the telescopic stage with the product arm. Five-axis AC servodrive,also suitable for in-mold labeling and in-mold inserting application. After installing the manipulator,the productivity will be increased by 10-30% and will reduce the defective rate of products,ensure the safety of operators,reduce manpower and accurately control the output to reduce waste.

Five-axis driver and controller integrated system:fewer signal lines,long-distance communication,good expansion performance,strong anti-interference ability,high accuracy of repeated positioning,can simultaneously control multiple axes,simple equipment maintenance,and low failure rate.

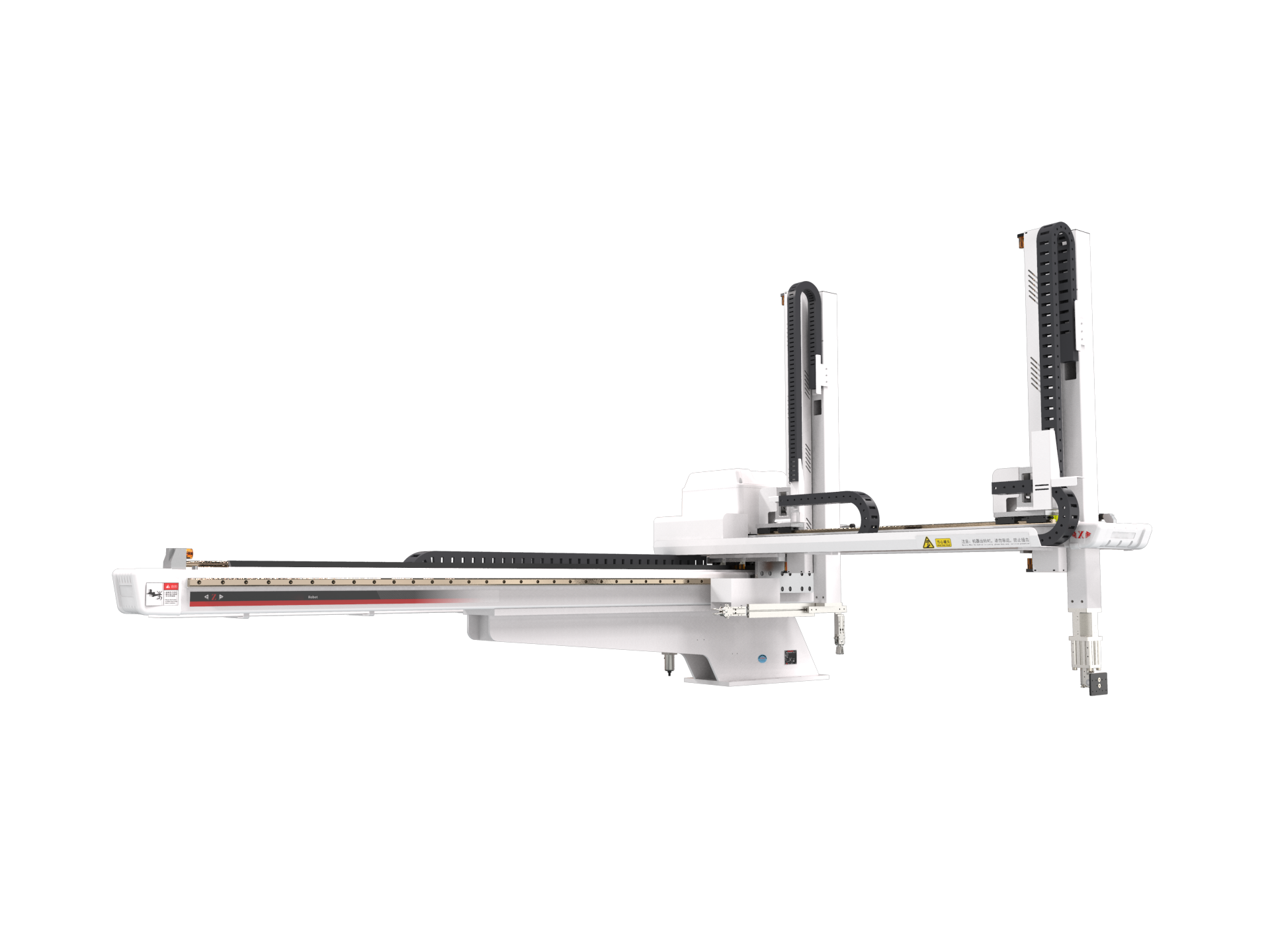

BRTR17WDS5PC/FC series applies to all types of horizontal injection machine ranges of 750T-1200T for take-out products and sprue. The vertical arm is the telescopic stage with the product arm. Five-axis AC servodrive,also suitable for in-mold labeling and in-mold inserting application. After installing the manipulator,the productivity will be increased by 10-30% and will reduce the defective rate of products,ensure the safety of operators,reduce manpower and accurately control the output to reduce waste.

Five-axis driver and controller integrated system:fewer signal lines,long-distance communication,good expansion performance,strong anti-interference ability,high accuracy of repeated positioning,can simultaneously control multiple axes,simple equipment maintenance,and low failure rate.

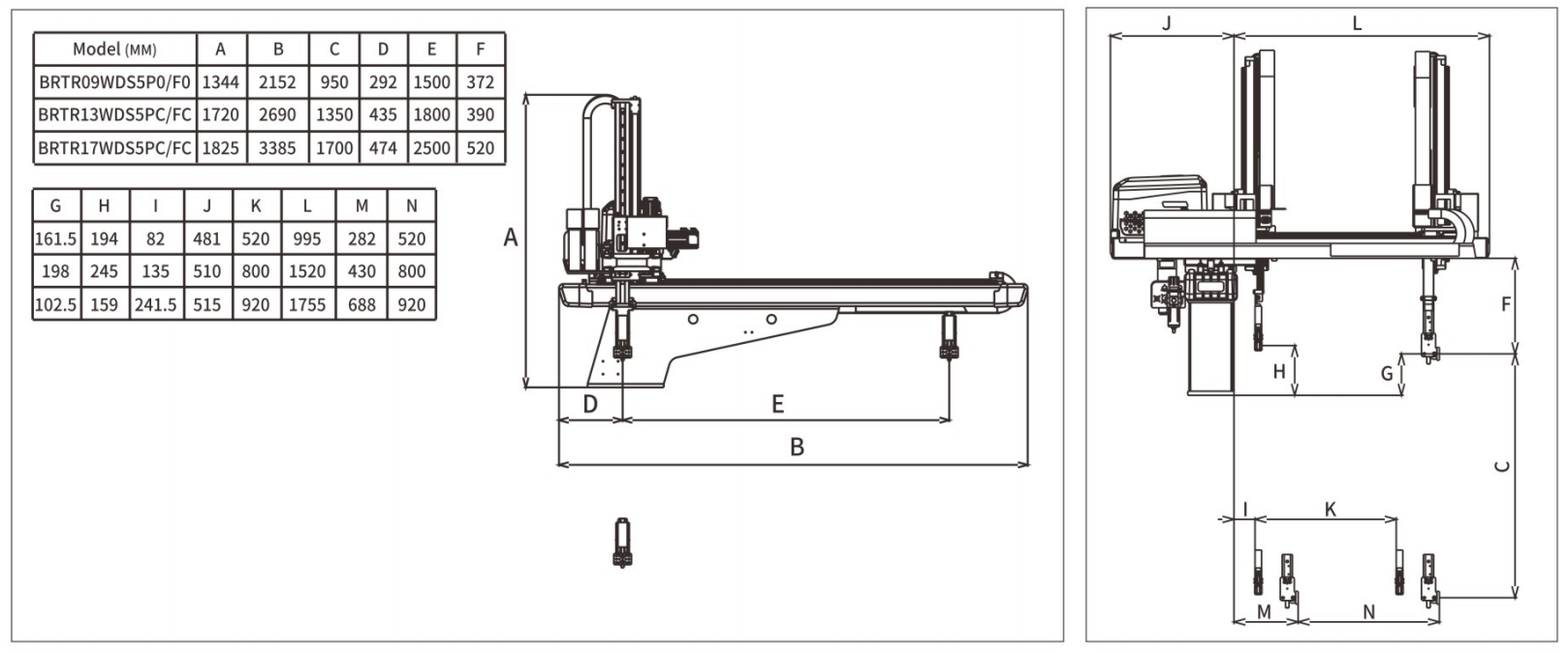

Five-Axis Servo Manipulator Main Specification

| Model: | BRTR09WDS5P0/F0 | BRTR13WDS5PC/FC | BRTR17WDS5PC/FC | ||||

| Recommended I.M.M: | 160T-320T | 360T-700T | 750T-1200T | ||||

| Traverser Driven: | AC Servo motor | AC Servo motor | AC Servo motor | ||||

| Model of EOAT: | Four suctions Two fixtures | Four suctions

Two fixtures | Four suctions

Two fixtures | ||||

Traverse Stroke: | 1500mm | 1800mm | 2500mm | ||||

Crosswise Stroke: | P:520mm R:520mm | P:800mm R:800mm | P:920mm R:920mm | ||||

Vertical Stroke: | 950mm | 1350mm | 1700mm | ||||

Max.loading: | 8kg | 10kg | 15kg | ||||

Dry Take Out Time: | 1.5s | 2.67s | 3.72s | ||||

Dry Cycle Time: | 5.61s | 8.66s | 12.72s | ||||

Air Consumption(NL/cycle): | 4 | 6.8 | 15 | ||||

Repeatability: | ±0.05mm | ±0.05mm | ±0.05mm | ||||

Power source: | 2.91kVA | 3.76kVA | 3.67kVA | ||||

Weight: | 246kg | 450kg | 800kg | ||||

Application scenarios: | Injection molding industry | Injection molding industry | Injection molding industry |